This article is part of the Mining Insights Exchanges series whereby Digital Mining Solutions invites guest writers to exchange ideas and expertise. Th is article is written by Alex Hays, Cofounder/President of Orion & Taurus, VP of Ops at Adakon Energy. Orion & Taurus delivers specialized education for ASIC miner repair. In the fast-paced world of Bitcoin mining operations, where every decision can impact profitability, the importance of understanding ASIC repair cannot be overstated. In this article Alex delves into the following topics:

What is a Repair?

Three Tiers of Severability

To Repair or Not to Repair That is the Question

Replacement vs Repair

Determine Cost-Effectiveness

Catastrophic Events

In Conclusion

What is a Repair?

In Bitcoin mining, a repair is a process by which you restore a Bitcoin server to its properly functional state. Inside of this, you have three types of actions: changing swappable parts, printed circuit board cleaning, and PCB board level repair/rework.

With a deep understanding of miner repair, operators gain the ability to make informed decisions on capital allocation, ensuring that resources are directed towards areas that yield the highest returns and minimize unnecessary expenditures.

Three Tiers of Severability

ASIC repairs can be divided into three tiers of severability, each presenting unique challenges and considerations.

Tier 1 repairs such as those related to Foreign Object Debris (FOD) or software issues, typically have minimal impact on hashboards and can be resolved without heating the PCB. These issues, including organic material build-up causing shorting, can often be remedied through proper PCB cleaning.

This tier requires a base level knowledge of printed circuit board construction, signal flows, and software interface. The repair actions potentially include replacing swappable parts, PCB cleaning, and software updates.

Tier 2 repairs are those in which operators encounter repairs involving the replacement of surface-mounted components like resistors, capacitors, or temperature sensors which fall under the repair actions of PCB repair/rework. These repairs are generally reliable if proper ESD mitigating procedures are followed, but they do carry inherent risks due to the need for heat during the repair process. This category may also include minor trace repairs with small breakage points, further adding to the complexity.

Tier 2 requires skills in PCB troubleshooting and moderate to advanced micro soldering skills given the size of the components and the existence of a heavy ground plane.

Tier 3 repairs also fall under the repair/rework category and represent the most significant challenges, often requiring major reconstruction efforts such as replacing corroded pads or even replacing one or multiple individual ASICs, which are bottom-terminated components. These operations can be labor-intensive and pose risks of damaging surrounding parts on the board due to the highly elevated temperatures involved.

To Repair or Not to Repair That is the Question

Evaluating the risk/reward decision on whether to attempt a repair job requires a thorough understanding of each unique circumstance and the professional knowledge of the repair techniques required to accomplish the goal of restoring the unit to a fully functional state.

Only an informed operator can make this determination, considering the various degrees of risk associated with repairs. Using data to drive decision-making and having a fundamental understanding of ASIC repair arms your team with the tools needed to navigate these challenges effectively.

The value equation for ASIC repair risk/reward is dynamic with multiple factors, these are the most important variables:

Value of the machine (replacement cost).

Profit Potential.

Costs of repair fulfilment (labor, parts, logistics).

Lost profit during the downtime for repairs.

Reliability of the repair.

The reliability of the repair is overlooked the most, however, this is the most important factor since a successful outcome is primarily the result of a competent technician.

Replacement vs Repair

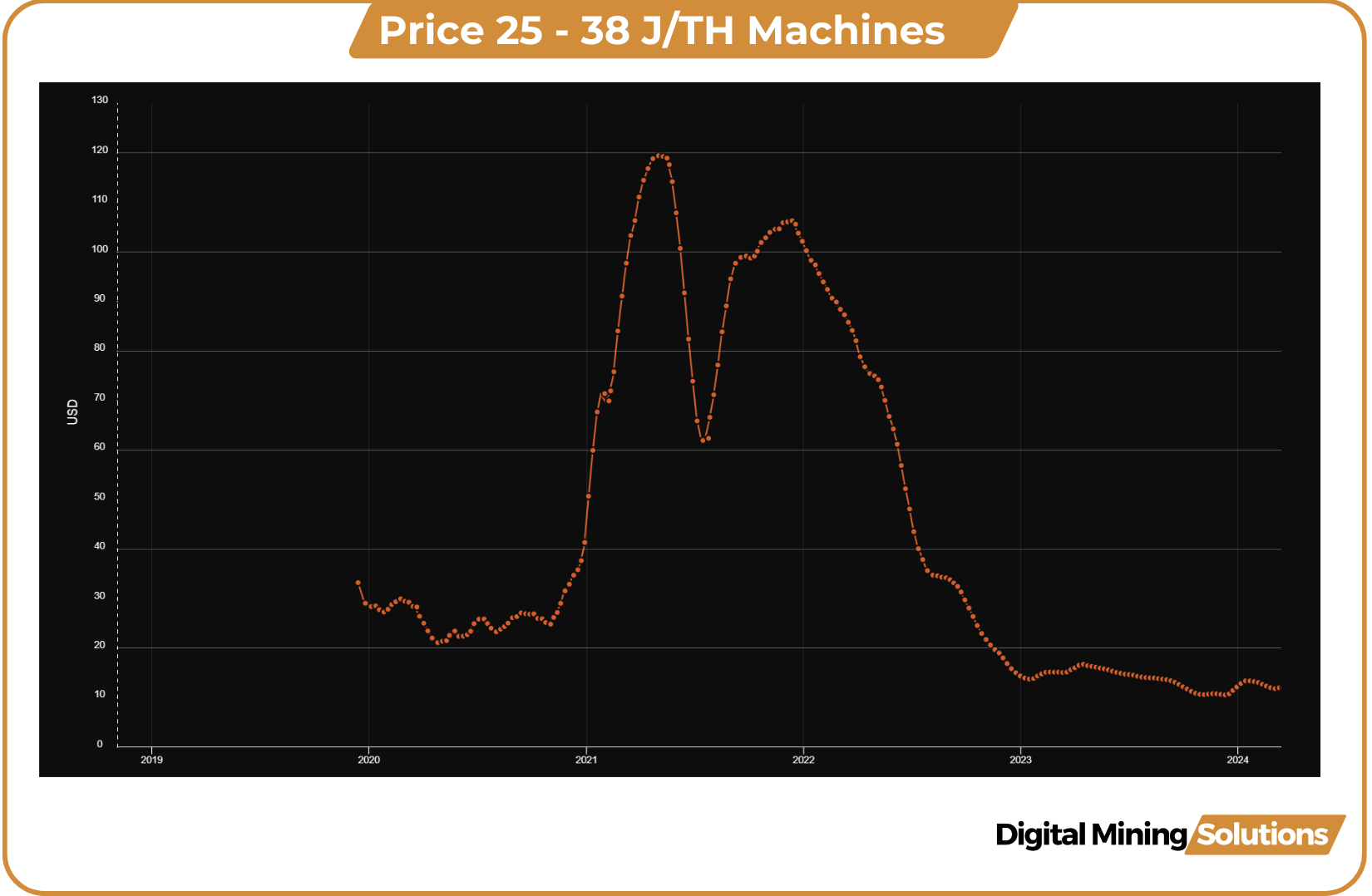

The replacement cost of the miner depends on the timing and availability of the miners. During the 2021 bull market, miner prices skyrocketed to over $12,000. Currently, the same miners are being sold for $1,200.

If you decide to fix the miner, you will have to weigh the profit potential based on how long your unit stays online. In the traditional PCB industry this is called a “latent failure”. Meaning a repair can initially be “successful” but will fail sometime before the ROI occurs. Latent failures are one of the main risks associated with electrostatic discharge (ESD).

At Orion & Taurus all procedures include strict ESD mitigation procedures to protect client units. A systematic approach is implemented to ASIC repairs which includes documenting the initial condition along with the serial numbers, thorough cleaning, inspection, diagnosis, repair, and Quality Assurance inspection. Inspection cards are used to communicate issues clearly, with severity levels clearly noted. A picture exhibit file and report of each miner is also provided. This information arms the mining operator with the ability to start a miner history log file to keep records. Using this data, the operators is able to evaluate a risk/reward decision before sending the miner in for repair.

Alex Hays Tweet

Determine Cost-Effectiveness

When it comes to allocating resources for repairs, a strategic approach is essential. By accurately evaluating the repair needs and potential costs associated with restoring a miner’s reliability, operators can weigh the investment against the anticipated returns and determine the most cost-effective course of action.

If the operator values uptime and efficiency, having extra parts will on hand will help achieve the goal. The number of extra parts such as control boards, fans, and PSUs depend on the size of the mining operation and environmental factors. Failures with control boards and power supplies are common.

Another strategy is to purchase batches of the same type of unit and consolidate parts from other units to continue to maintain full uptime efficiency. For this option, operators can train personnel in Tier 1 repairs which are much easier than developing talent with micro soldering skills needed for Tier 2 and Tier 3. This strategy works really well during a bear market when miner prices are depressed.

Catastrophic Events

A client of Orion & Taurus experienced a catastrophic event which greatly affected a large portion of a mining farm at once. In stead of diagnosing all miners, the team took a 10% sample size of the units and produce a detailed report on the conditions. The report issued recommended scrapping the whole lot since the investment would not likely yield a reliable result. This strategic approach not only safeguards against overspending on futile repair attempts but also ensures that resources are allocated efficiently to maintain operational reliability and profitability in the competitive Bitcoin mining landscape.

In Conclusion

Understanding the nuances of ASIC repair empowers operators to optimize their operations and ensure long-term profitability. By strategically managing repair processes, operators can minimize downtime, reduce unnecessary expenditures, and maximize returns on investment. This proactive approach to repair management is crucial in navigating the dynamic and competitive landscape of Bitcoin mining.

Mastering ASIC repair education is a strategic advantage for Bitcoin mining operators looking for another edge over other mining outfits. Knowing the severity of the miner repairs will arm the operator with the knowledge to allocate capital wisely. In doing so, operators can be proactive instead of reactive when evaluating the risk/reward decision on the stated variables. With the right knowledge and strategic approach, operators can make informed decisions, allocate resources effectively, and maintain operational reliability and profitability.